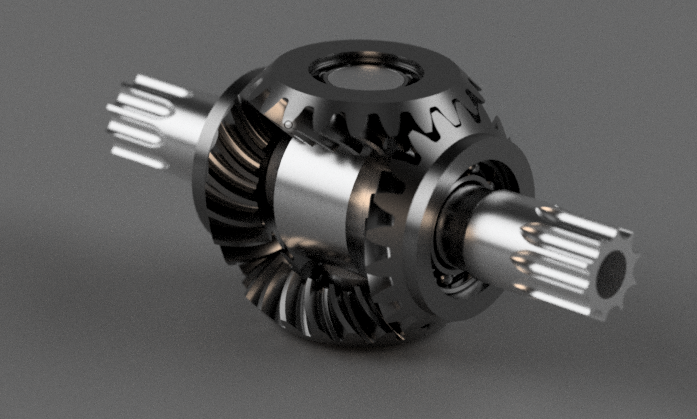

Proven Technology – New Advancements

Driven combines and builds on the last 20 years of hybrid vehicle innovations and over 100 years of bevel differentials by putting a differential planetary system at the mid-drive of an e-bike. This differential allows for two inputs (a rider and electric power), to combine into one output that drives the back wheel.