The Future is Micromobility

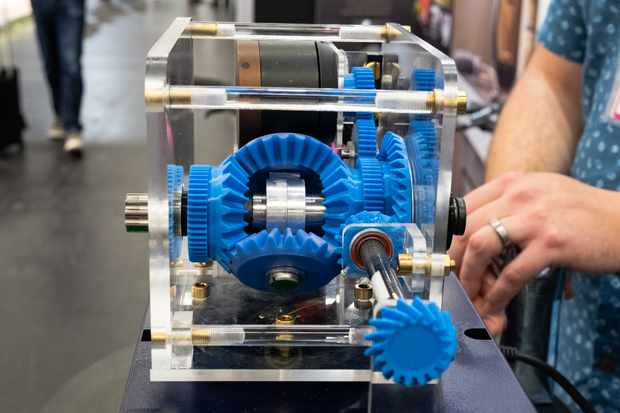

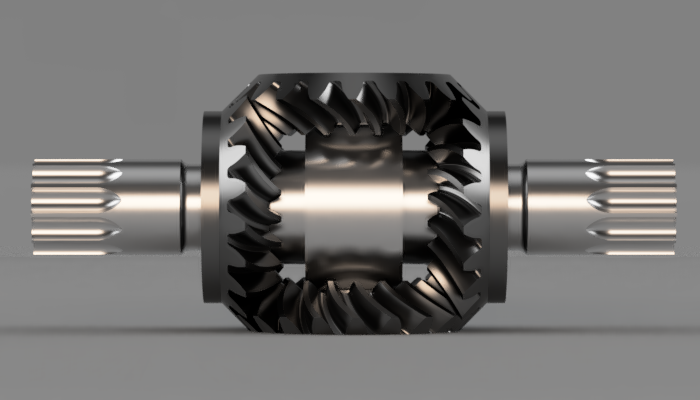

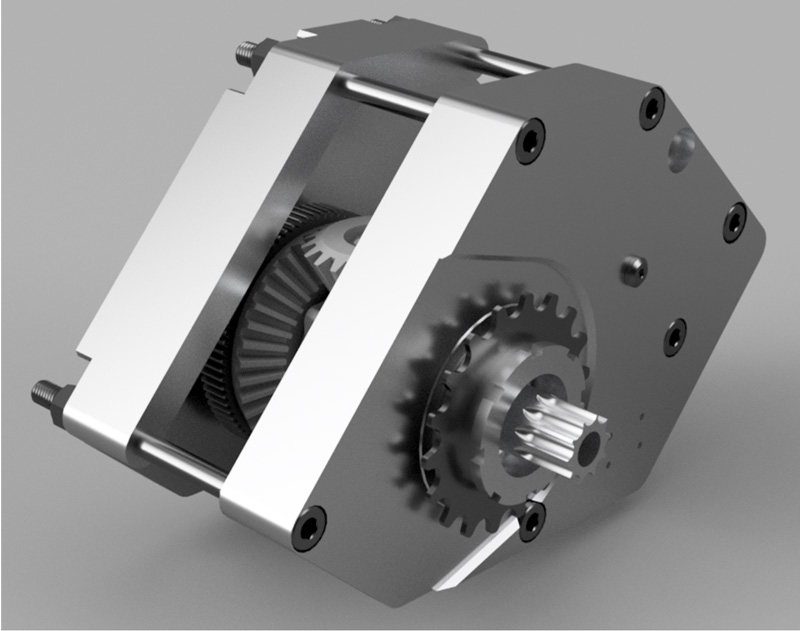

Micromobility is revolutionizing the way we work, move and play. The demand for affordable, clean, fun, and easy to maintain is only growing. Driven is poised to fulfill that need with the Orbit Drive. Like the leap between the invention of the automobile and the Model T, Driven is not the first company to develop an e-bike or stepless transmission (eCVT), but we have developed the natural evolution of the technology to the e-bike that opens the door to expanding the micromobility segment as a whole.